Q-Bot’s underfloor insulation (UFI) is a completely different system from loft spray foam. It is installed in a different part of the home, under carefully controlled conditions, using AI, robotics and full post-installation audits to guarantee quality.

Our process transforms a cold, draughty floor into a warm, dry, energy-efficient foundation with over 5,400 successful installations and zero failures.

Warm Floor vs. Cold Roof: The Building Science

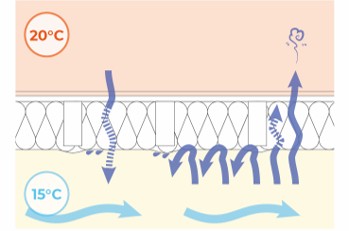

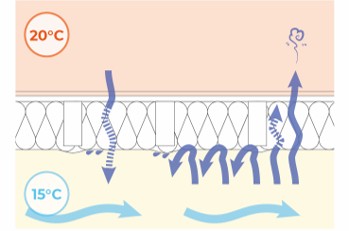

In any insulation project: wall, roof, or floor, the safest approach is to keep the structure on the warm side of the insulation.

That’s exactly what Q-Bot does.

Our closed-cell spray foam is applied to the underside of the floorboards, creating a warm floor. The timber remains inside the insulated envelope, staying dry, stable and protected.

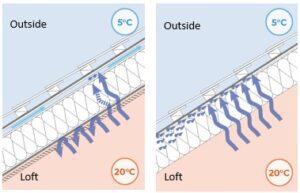

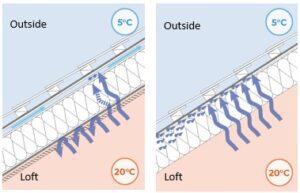

Loft foam often does the opposite, leaving roof timbers on the cold side. When ventilation routes are blocked or omitted, condensation can form. This is the root cause of many of the loft-foam mortgage issues seen in the press.

When warm, moist indoor air meets a cooler surface, it reaches the dew point, the temperature where water vapour condenses into liquid. In buildings, this is the point where damp and decay risks begin.

Q-Bot’s underfloor insulation design keeps the timber above the dew point. By applying a continuous, closed-cell layer to the underside of the boards, the dew point is moved below the insulation, into the ventilated void, where any moisture can dissipate naturally.

Independent hygrothermal modelling by Enhabit (2021) and Greengauge Building Energy Consultants (2021) confirmed this. Their analysis found that timber moisture content stabilises between 11–14 %, well below the 18 % threshold for fungal activity, and that relative humidity within the floor void decreases after installation.

This is consistent with the UK Government’s BEIS “Guide to Best Practice – Suspended Timber Floors” (2020), which highlights that maintaining thermal continuity and avoiding cold bridging are key to preventing condensation and mould.

Q-Bot’s approach is validated by three key studies that define best practice for underfloor insulation and moisture control:

BEIS (2020) – “Retrofit Floor Insulation: Suspended Timber Floors – Guide to Best Practice”

Establishes how to insulate suspended timber floors safely: emphasising adequate cross-ventilation, avoidance of cold bridges, and the requirement that the structure remains dry and free of condensation in line with Building Regulations Part C.

Enhabit (2021) – “Q-Bot Hygrothermal Performance Research”

Used WUFI® hygrothermal modelling to show that Q-Bot’s insulation moves the dew point below the foam layer, keeping floorboards and joists warm and dry. Moisture levels remained stable at 11–14 %, and void humidity decreased after installation.

Greengauge Building Energy Consultants (2021) – “Hygrothermal Risk Analysis Report”

Confirmed Enhabit’s findings across multiple floor types, identifying no interstitial condensation risk even in cold, humid conditions, and verifying full compliance with BS 5250:2021 and PAS 2035.

Q-Bot applies established building science through robotics and AI to deliver moisture-safe, high-performance insulation, making proven theory work perfectly in practice.

Built-In Compliance and Quality Assurance

Every Q-Bot installation follows Beis Best Practice, PAS 2035 retrofit standards and UK Building Regulations for ventilation, moisture control, and safety.

We go beyond compliance with four layers of protection:

- Pre-install suitability checks – We assess every property for ventilation, service locations, and timber moisture content before installation begins.

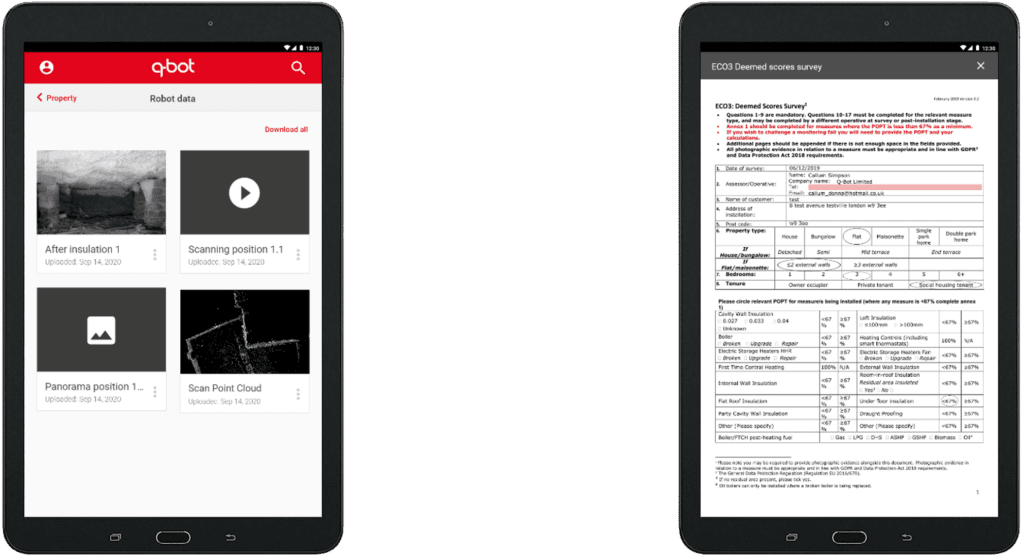

- Robotic installation – Our robots apply insulation with precision sensors and live video feedback for even coverage.

- 100% QA audit – Every job is reviewed by our internal Quality Assurance team before certification.

- AI-driven IMS platform – Our proprietary Install Management System uses artificial intelligence to analyse video data, tag potential anomalies, and continuously improve quality across thousands of homes.

Every Q-Bot job is robotically recorded. Footage, images, and data are uploaded to our digital audit trail for permanent reference.

Airbricks and vents are inspected and, if needed, upgraded to maintain proper cross-ventilation — an essential difference from other insulation measures, which often blocks roof airflow.

Every Q-Bot installation leaves a verifiable digital record that homeowners, surveyors, and retrofit coordinators can review at any time.

Across nearly 6,000 installs, Q-Bot has recorded zero failures: a record that sets us apart from many traditional insulation schemes reporting high failure or damp rates.

Proven Results: Drier Floors, Lower Humidity, Greater Comfort

Independent studies have shown Q-Bot’s system improves both comfort and building health:

- NEA (2016–17): Floor-void humidity dropped by up to 30%, indoor humidity by 6%.

- Greengauge (2021): Timber moisture content decreased post-installation.

- Leeds Beckett University (2019): Measured a 24% reduction in total dwelling heat loss.

By creating a “warm floor,” Q-Bot moves the dew point below the timber, keeping the structure dry and healthy.

Will this affect my mortgage?

Recent media coverage about spray foam and mortgages has centred on loft installations, where the foam was applied directly to roof tiles or rafters, often outside of Building Regulations and without required ventilation.

These situations have nothing to do with Q-Bot’s work.

Q-Bot’s underfloor system is completely different:

- ✅ Installed beneath suspended timber floors, not in the roof.

- ✅ Fully compliant with Building Regulations Part C and follows the BEIS Best Practice.

- ✅ Approved under TrustMark and covered by a 25-year IAA Insurance Backed Guarantee.

- ✅ Supported by AI-driven quality assurance and a zero-failure record across more than 6,000 installations.

To date, no mortgage adviser or lender has ever instructed the removal of a Q-Bot installation because our approach is transparent, traceable, and fully documented.

We provide all paperwork and certification advised by mortgage lenders, the Property Care Association (PCA), and independent retrofit bodies, including:

- Installation certificate and IAA guarantee.

- QA and video audit trail from our Install Management System (IMS).

- Pre-install moisture readings and ventilation verification.

- Post-install quality and compliance statement.

- Declaration of Conformity

This clear evidence allows lenders, valuers, and surveyors to see exactly what’s been installed and how it complies with regulations: giving complete confidence that Q-Bot’s underfloor insulation is mortgage-friendly, safe, and fully documented.

For more information, please visit our Q-Bot main website.